Vindum CV Automated High-Pressure Valves

Manufacturer: Vindum Engineering, Inc.

Model Number: CV-xxx (see Specifications)

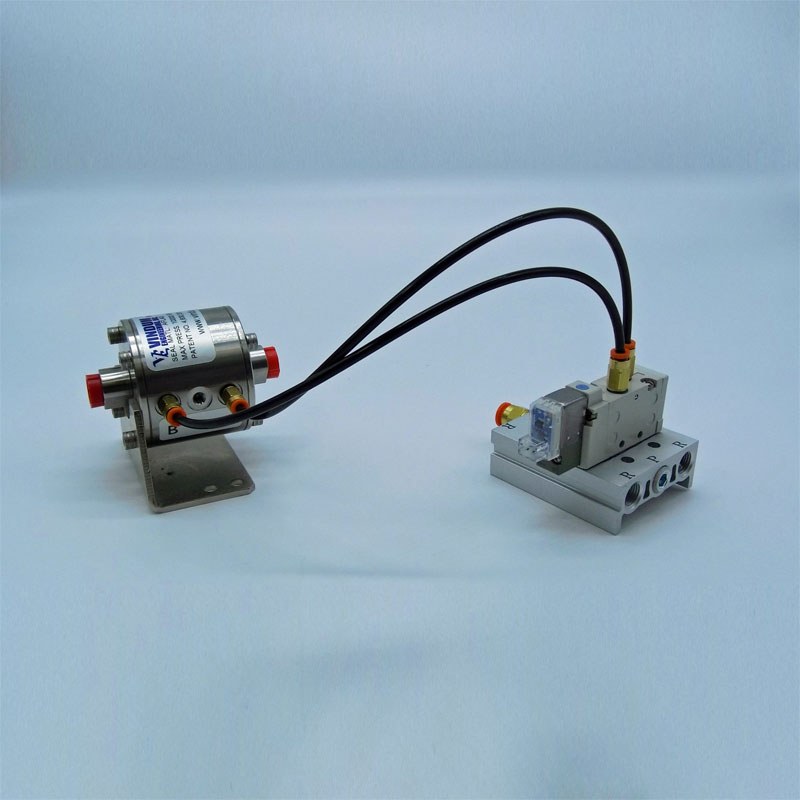

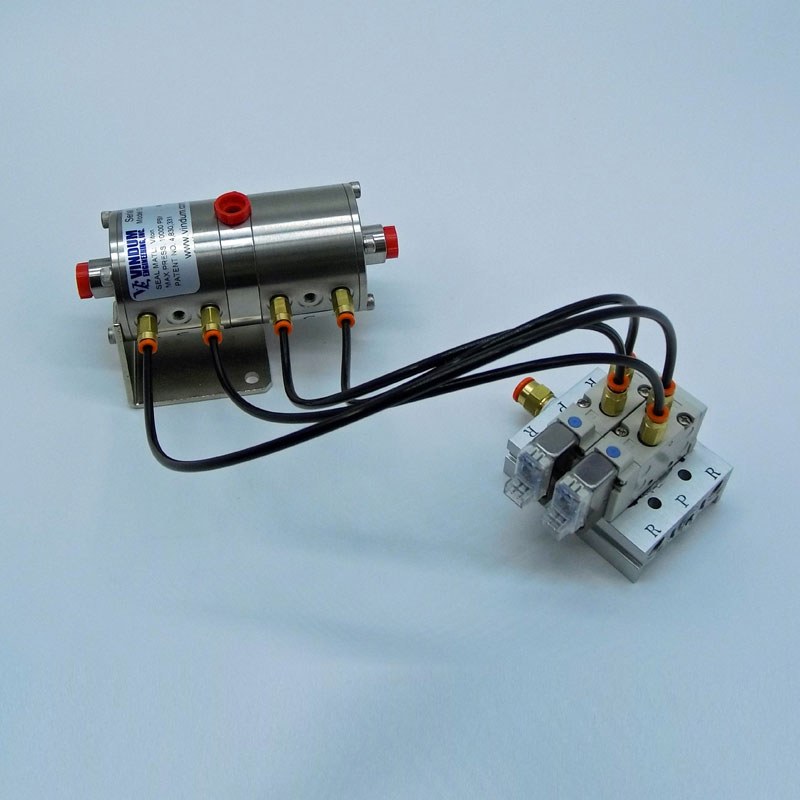

The features, durability, and reliability of CV-Series valves make them a cost-effective solution for the most exacting laboratory high-pressure flow-control requirements. The patented constant-volume design is only one of the outstanding features of these 2-way and 3-way valves. Originally developed for pulse-free fluid flow in dual-piston displacement pumps, the design is widely used in a range of high-pressure applications. CV valves work with 1/16", 1/8” or 1/4" tubing, depending on the valve model.

Features of Vindum CV Valves

- Range of models: up to 25,000 psi and 300C

- Standard 2-way or 3-way/4-position models

- Rapid open/close (~0.1 second) using compressed air (70-100 psi)

- Remote actuation using solenoid pilot valve (12V or 24V)

- Low internal volume and no trapped fluid

- Durable and easily rebuildable

- Gas-tight seal, able to hold a vacuum

- Variety of O-ring seal materials available

- Custom designs available

Applications for CV-Series Valves

- Remote or centrally controlled systems

- High temperature processes or experiments

- Oil & gas core flooding and PVT experiments

- Chemical or refining pilot plant systems

- Process development systems

- Multi-piston displacement pumps (pulse-free flow)

Categories: Constant Volume CV-Series Automated Valves

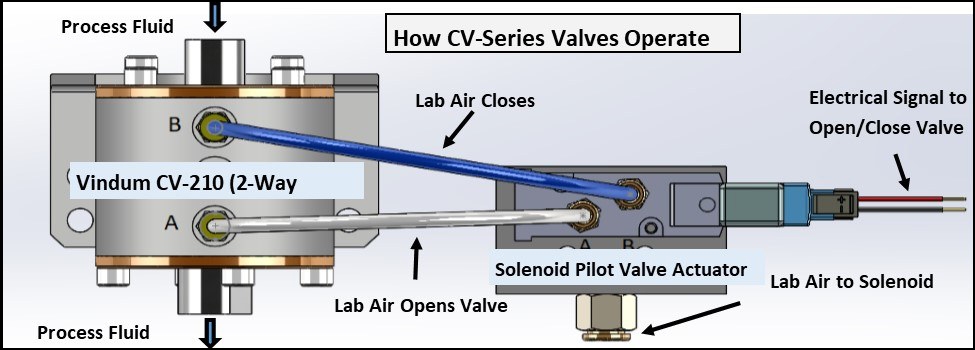

The Vindum Engineering CV High Pressure Valves are available in two configurations; either as a 2-position, on/off valve, or a 3-way, 4-position valve. The CV Valves are air-actuated, constant-volume valves with a switching time of less than 0.1 second. They are typically used as switching devices in high-pressure fluid flow systems. The valves are designed so that no fluid is displaced (creating no pulse) when they are opened or closed. This allows them to be useful in systems requiring constant volumes or constant pressures during the switching cycle.

Features of CV-Series Valves

- Rapid actuation (~0.1 sec) via compressed air (75-100 psi)

- Very low internal volume with no trapped fluid

- Pulse-free open/close (constant-volume design)

- Work with liquids or gases (including CO2)

- Applications up to 25,000 psi and 572°F (300°C).

- 2-Way or 3-Way valve models

- Remotely actuated via solenoid pilot valve and compressed air is perfect for centralized control systems

- Hastelloy wetted parts (option) for corrosion resistance

- Wide range of seal materials available (Viton, Teflon, Buna-N, UHMW-PE, EPDM, AFLAS, Chemraz, and others)

- Easily serviceable and rebuildable

Click on the Video below to see the features of the Vindum CV-Series Valves

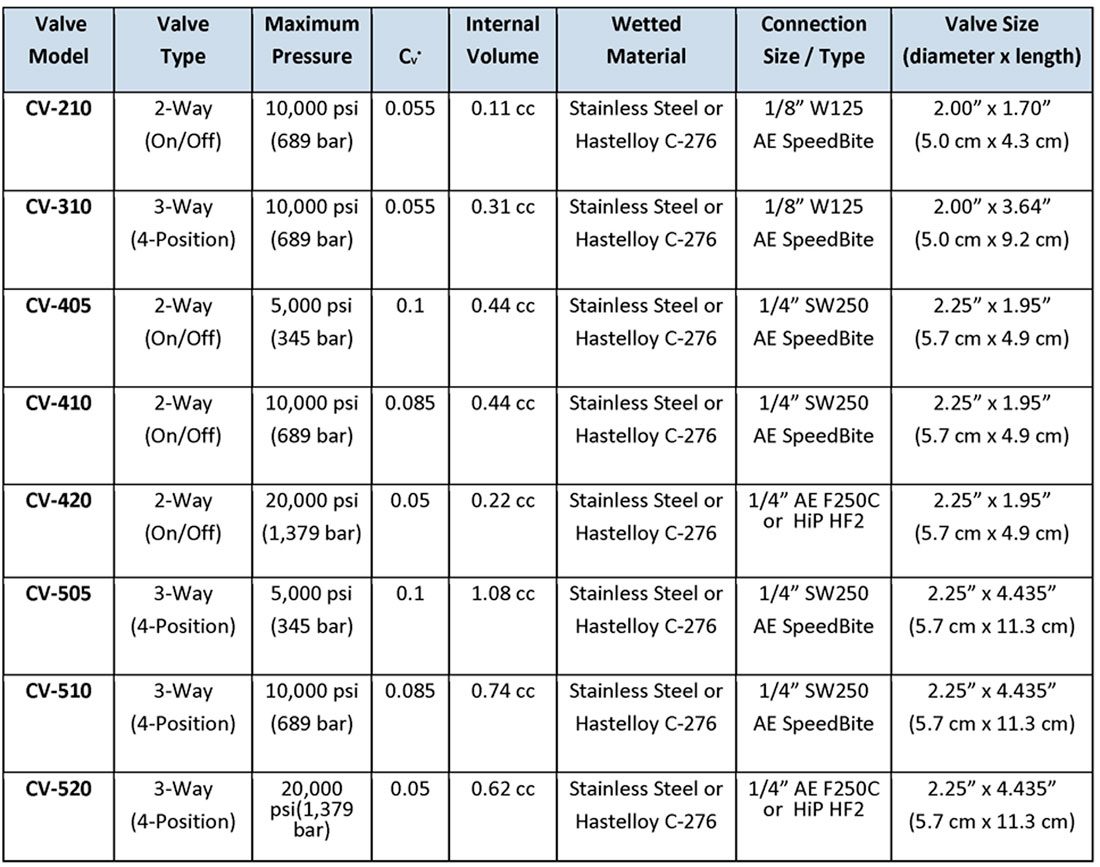

Specifications for Vindum CV-Series valve models are shown in the table below. Click here to Download the PDF Document.

* Flow coefficient (approximate), US gallons of water per minute with 1 psi pressure drop @ 60F

CV-Series valves use an O-ring fluid seal design that has proven effective with a range of fluids. Viton is the standard O-ring material, but there are many other material options. The most common O-ring materials are listed below:

- Viton (FKM): 0°C-200°C, Elastomer. Excellent for oils & most chemicals. Avoid phosphate esters and ketones. This is the standard O-ring material supplied, unless otherwise requested.

- Buna-N (NBR/Nitrile elastomer): several grades available. Continuous use to about 110°C, but HBNR compounds available to 150°C. Good for petroleum oils & fluids, water. Not recommended for ketones (MEK, acetone), strong acids >10% concentration), and halogenated or nitro hydrocarbons.

- UHMW-PE (ultrahigh molecular weight polyethylene – thermoplastic): Self-lubricating (low friction), long-wearing, excellent abrasion & chemical resistance (including petroleum oils, organic alcohols, ketones, and acids). Not recommended for use with highly oxidizing chemicals (eg, bleach) or chlorinated solvents (cause swelling). Maximum operating temperature 82°C.

- AFLAS (TFE/P or FKM elastomer): Excellent chemical resistance to most acids & bases, amines, petroleum oils & fuels, and steam. Good permeation resistance but not as resilient as Viton. Maximum operating temperature 204°C.

- Chemraz/Kalrez (FFKM): Excellent chemical, heat, and explosive decompression resistance. Expensive. Maximum operating temperature 249°C (higher in special formulation).

- Other: Other O-ring materials are available. Please contact Vindum Engineering to discuss.

Determining the best O-ring material for your application can be done with the help of several online resources that list chemical compatibility of many O-ring materials.

Click one of the links below for more details:

- Parker O-ring Handbook: Perhaps the most frequently cited reference for O-ring material compatibility

- Graco Chemical Compatibility Guide

- Marco Rubber & Plastics O-Ring Chemical Compatibility Guide

- Cole-Palmer Chemical Database

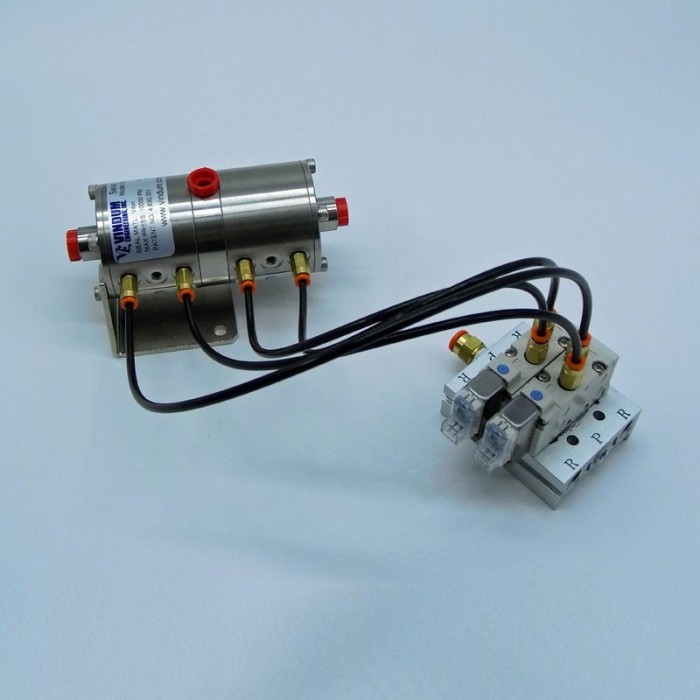

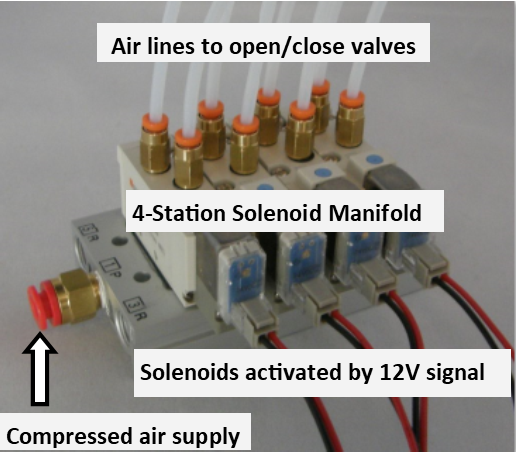

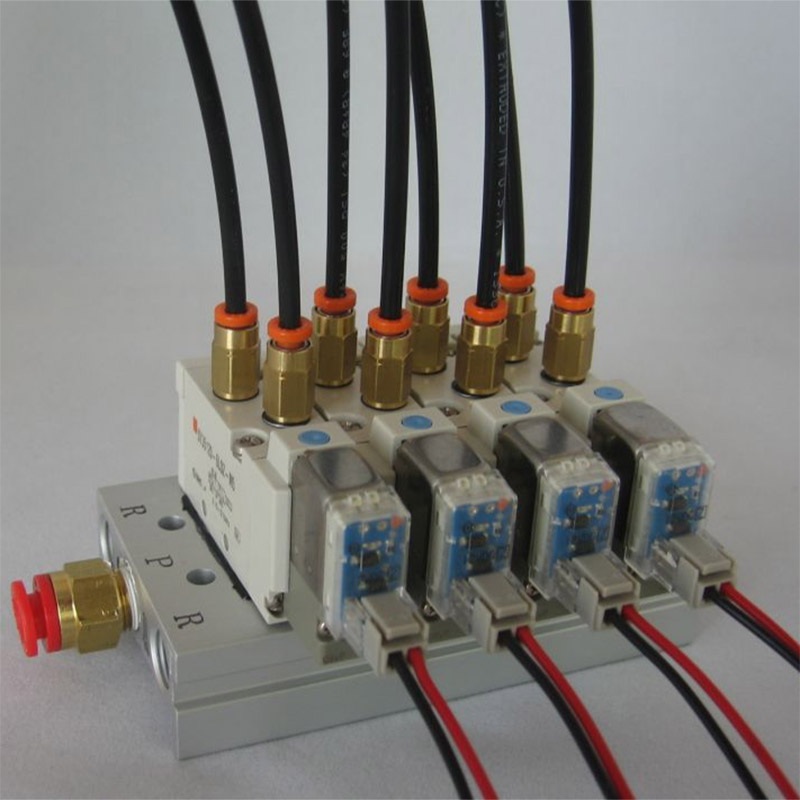

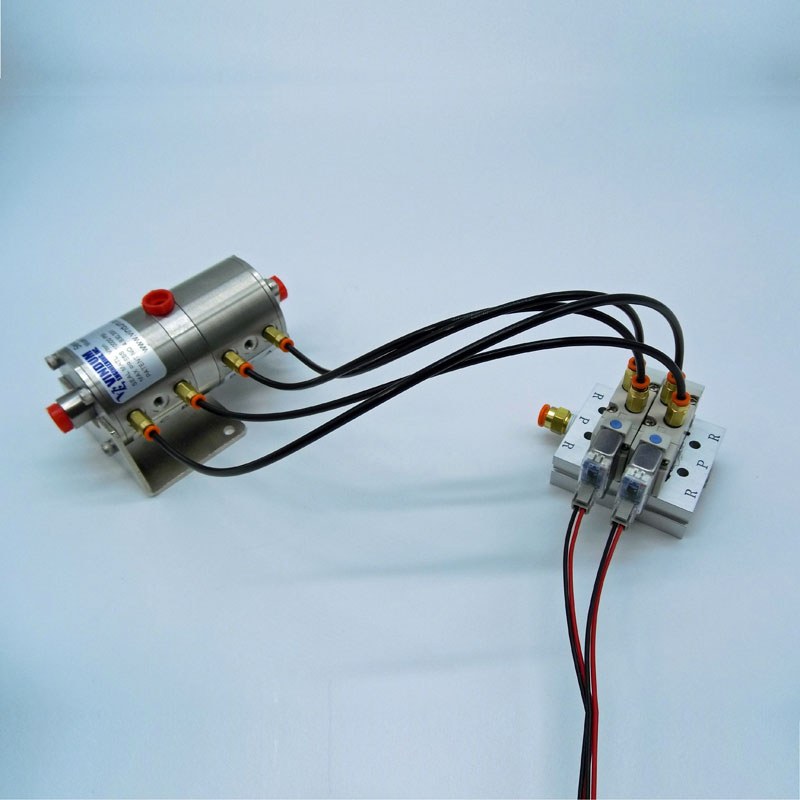

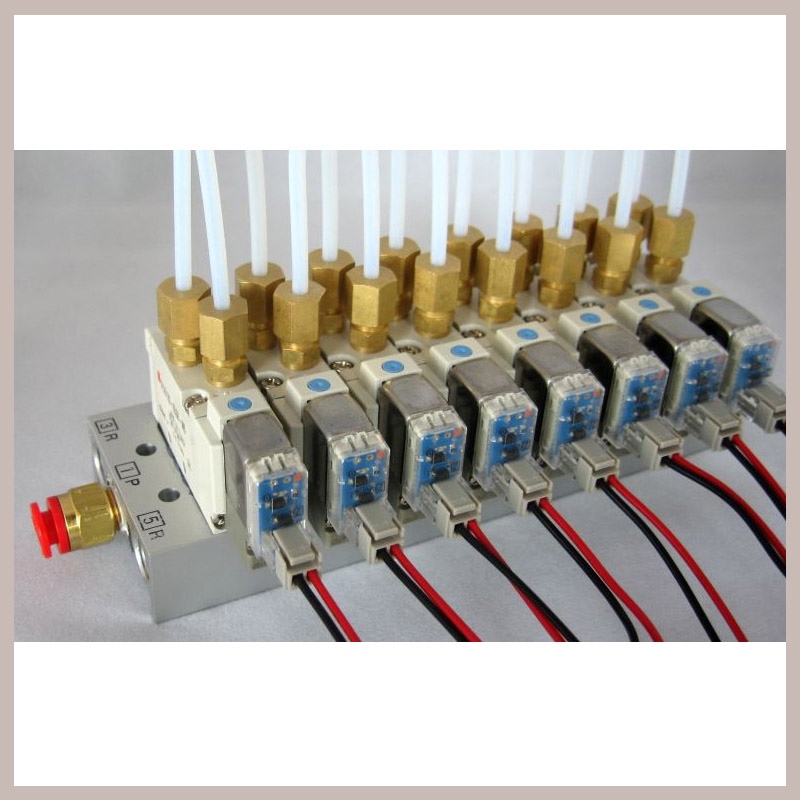

Vindum Engineering's CV valves are actuated by compressed air (75-100 psi), via solenoid pilot valves. Manifold assemblies, with 2-to-12 solenoids are available. The manifold has one air inlet fitting to supply compressed air to each of the mounted solenoids. Each solenoid actuates one 2-way CV valve.

Solenoid Pilot Valve Actuators

Manufacturer: Vindum Engineering

Model Number: CV-PV

Compressed air, between 75-100 psi, is used to actuate Vindum CV valves. Control of the compressed air is by a pilot valve, in which either a 12V or 24V signal actuates a solenoid that directs air to the pneumatic port on the CV valve. One position of the solenoid opens the CV valve; the other closes the valve.

We have many configurations available:

- 2, 4, 6, 8, 10, and 12 station manifold bodies

- 12 volt or 24 volt solenoid pilot valves (30mA current)

- Ambient or High-Temperature air fittings

When ordering, please specify solenoid voltage (12VDC or 24VDC), manifold size (2-12 solenoids), and application temperature (Ambient or High-Temperature).

We stock replacement parts and sealkits for all the CV valves. The photos on this page list many of the spares. To order replacement parts, please contact us, at support@vindum.com, with the model number of the valve and the part(s) you need. We’ll send you a quote, typically within 24 hours. We ship worldwide, from our California facility. Please specify if you need expedited or overnight shipping.

Spare Parts for CV-Series Valves

- Valve seal kits (seal, O-rings, and backup rings). Specify valve model.

- Air fittings. Specify ambient or high-temperature application.

- Pneumatic tubing. Specify ambient or high-temperature application.

- Fluid Connection (gland nut & ferrules). Specify 1/16", 1/8” or 1/4” connection and SS or HC ferrule.

User Guide

Instructional Videos