- Product Details

- Pump Design

- Specifications

- Continuous Flow

- VPware Software

- Control Options

- Heating and Cooling Jackets

- Support

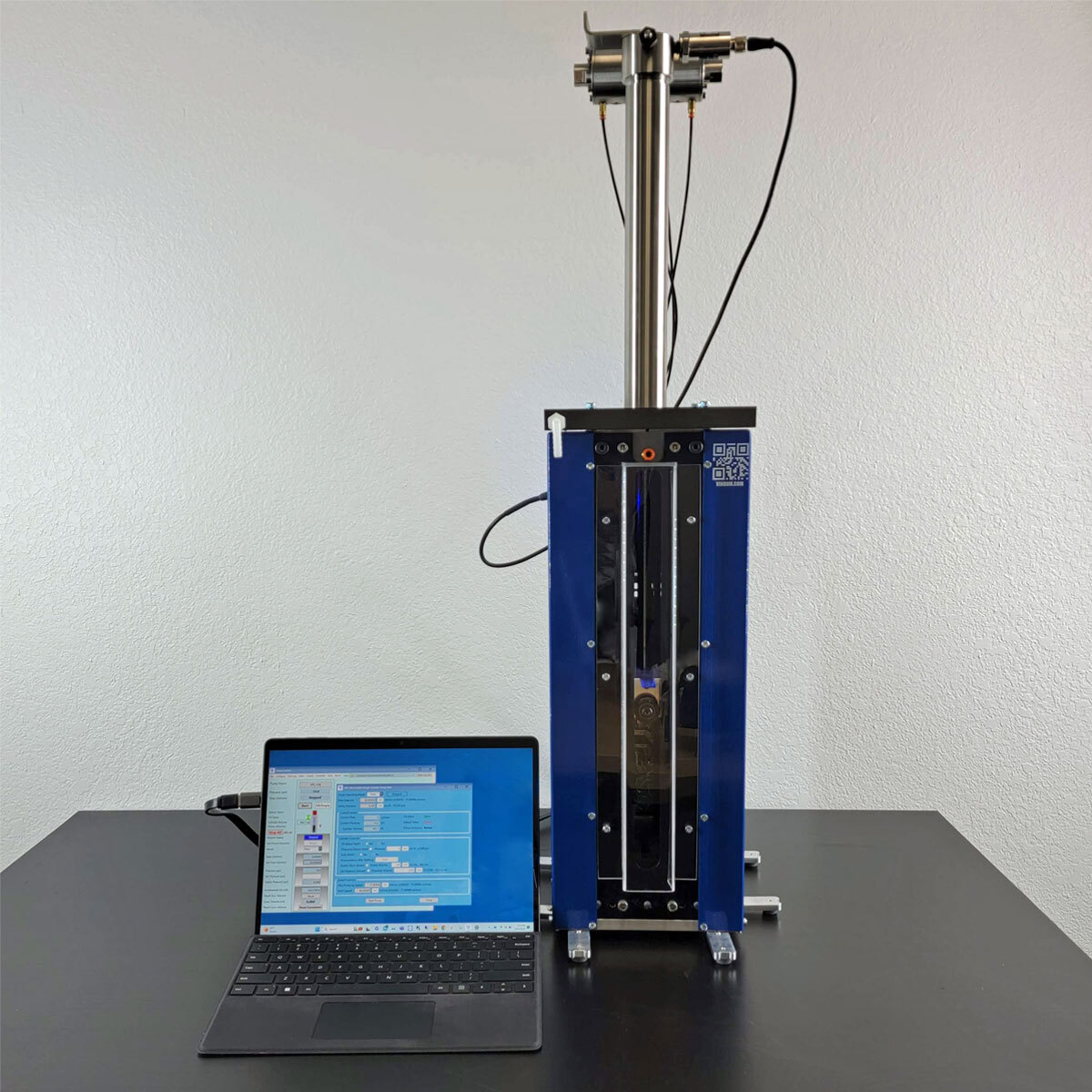

VIPR-Series High-Pressure Syringe Pumps

Manufacturer: Vindum Engineering, Inc.

Model Number: VIPR-Series

Vindum VIPR-Series syringe pumps offer unbeatable performance, capabilities, and pricing. VIPR pumps are ideal for applications requiring higher flow rates or fluids that are highly compressible, such as CO2.

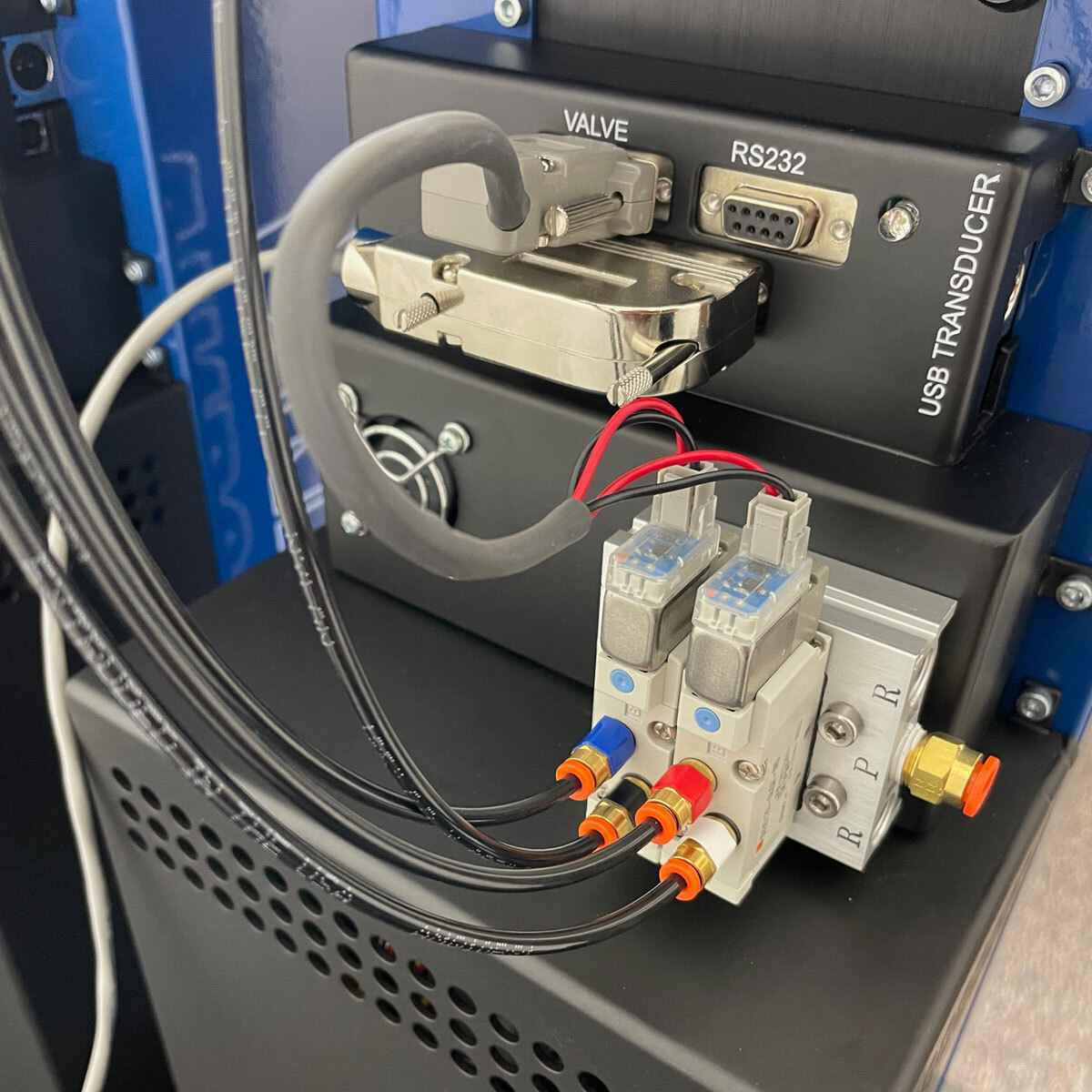

VIPR pumps are controlled by the same VPware PC software, or many other control options, including: Modbus, OPC UA, and analog/digital signals from PLCs. The pump's circuit board can also control external valves, such as the Vindum CV valves, which allows automated cycled pumping/refilling and other features not found on competing pumps. When equipped with automated valves, two VIPR pumps can be easily paired for pulse-free continuous pumping in either pressure or rate modes.

If you are looking for a laboratory syringe pump that is easy to use and is adaptable to a wide range of applications, take a minute to learn about our VIPR-Series pumps and then compare them to the competition. We will be happy to provide a quote and to answer any questions.

Features include:

- High-accuracy constant-pressure or rate modes, including cycled modes

- VPware control software included (works with any Windows 7+ PC)

- Dual ball screw drive for unbeatable longevity

- High-precision transducer included (0.1% error)

- Innovative cylinder wash system standard

- Visible interior with two drip trays help prevent damage from leaks

- Extra O-ring piston seal for pumping liquified gases, such as CO2

- Available Accessories: Tablet PC, heating/cooling jacket, and heating jacket

- Multiple control options, including mA or Vdc analog in/out

- Easily converted to continuous flow (requires 2 pumps with automated valves)

- Simple control interface, with most settings on one screen

- Available in either stainless steel or Hastelloy wetted parts

VIPR Pump Applications:

- Experiments with liquified gases, such as CO2 research

- Energy research (core flooding or PVT experiments)

- Chemical dosing or additive injection

- Any research requiring precise high-pressure fluid pumping

- Universities wanting high-capability pump at lower price that is easy to use

Categories: VIPR Syringe Pumps: High-Accuracy, High-Pressure, and Highly-Flexible

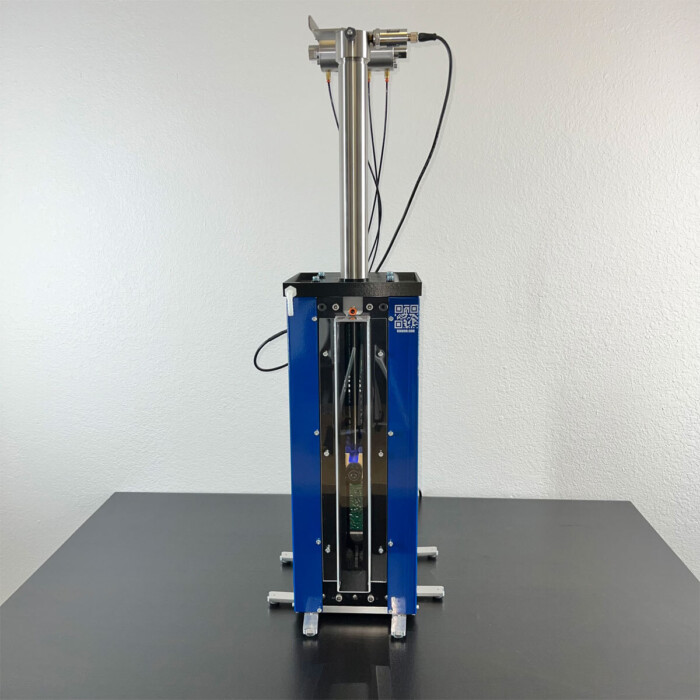

Design & features of Vindum VIPR-Series Syringe Pumps

- Single motor, dual ball screw drive system for smaller size and enhanced durability

- Designed for pumping liquified gases, eg, CO2

- Connect two VIPR pumps for continuous, pulse-free, pumping

- Planetary gearbox with zero hysteresis

- On-board computer provides millisecond motor control and automatic valve actuation

- High accuracy transducer (0.1% error) standard, for precise pressure control

- Automated valves (option) expands pump capabilities (required for dual-pump operation)

- Powerful VPware software, with graphing, ramping, and datalogging features

- Integrated cylinder wash system is standard

- Two drip trays contain any fluid leaks

- Optional Hastelloy wetted parts allow pumping corrosive fluids

- UHMW PE or Teflon piston seal options for better fluid compatibility

- Many control options, including analog/digital inputs & outputs (0-10Vdc or 4-20mA)

- Temperature-control jacket (option)

- Universal power supply: 110-240V / 50-60Hz service

- 2-Year Warranty included

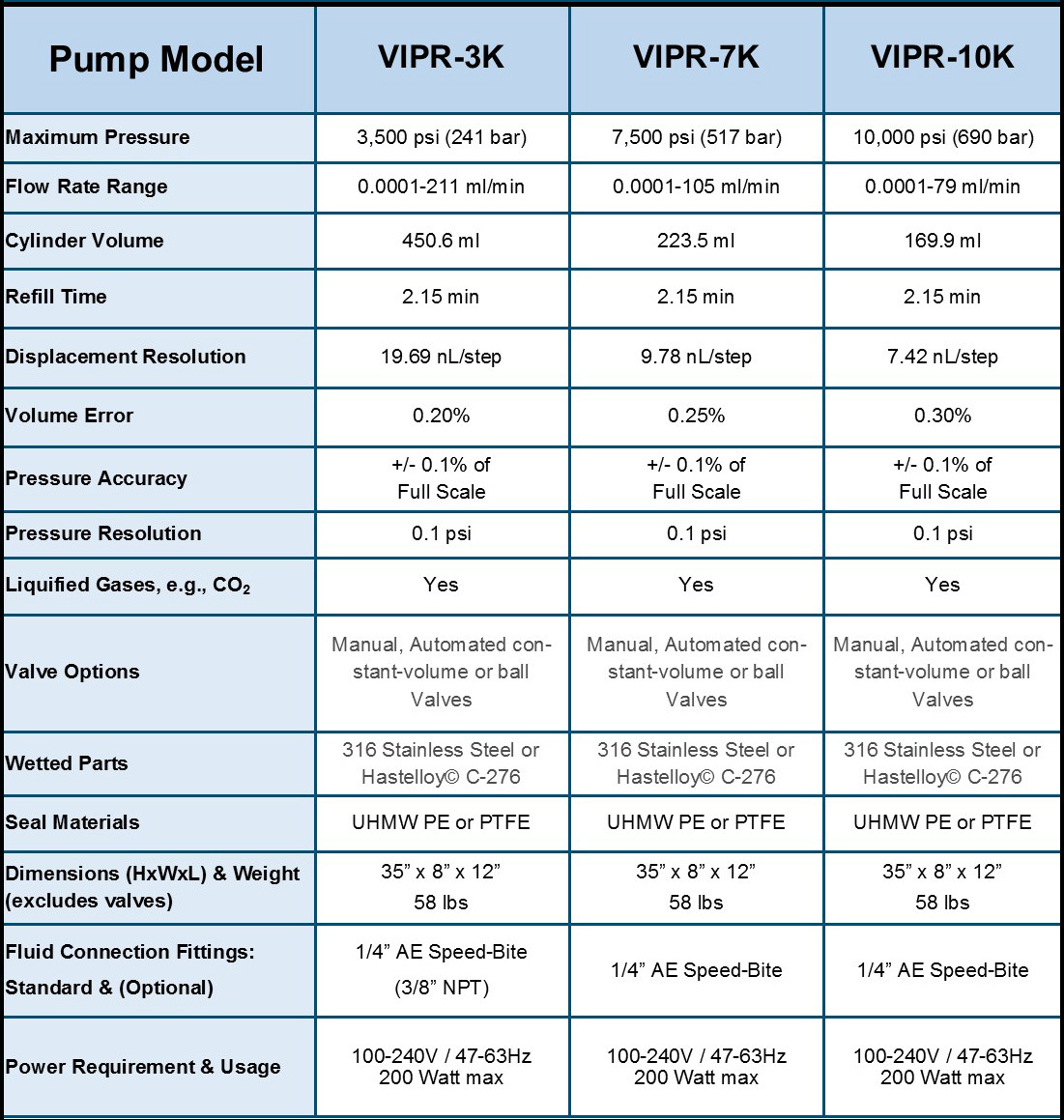

Specifications for VIPR Series Pump models are shown in the table below. Click here to Download the PDF Document.

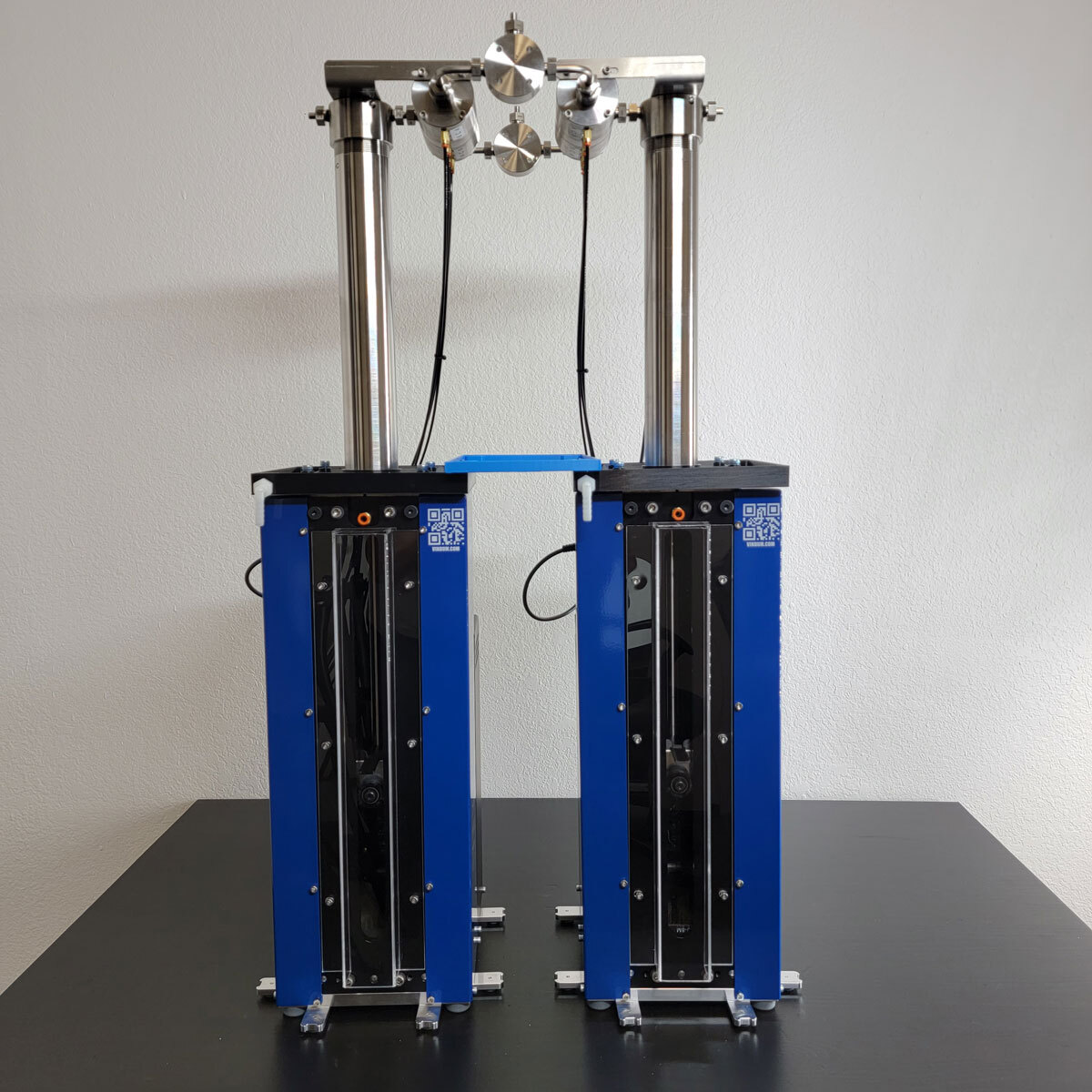

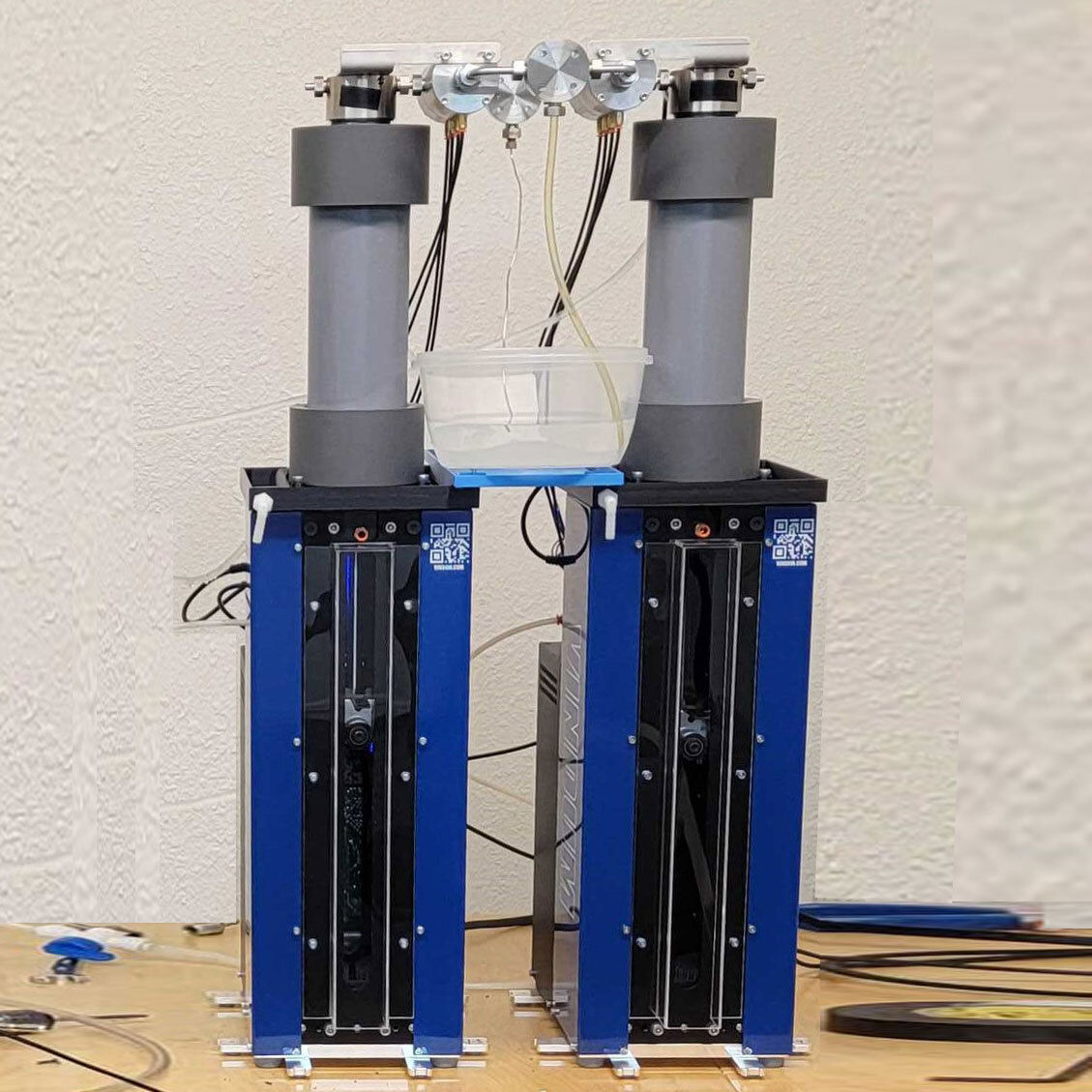

Two VIPR pumps can be easily configured for continuous, pulse-free, pumping. Simply connect together the Vindum automated valves of each pump, connect the special cable between the two pumps, and configure the VPware software to "pair" the pumps. See the photos below showing a dual-VIPR pump setup.

Once paired, the VIPR pumps are able to pump fluids continually and pulse-free, in either constant-rate or constant-pressure modes. While one pump is pumping, the other pump fills and pressurizes to match the pressure of the other pump, just like the smaller VP-Series pumps. In this configuration two VIPR pumps can deliver fluid continuously for days or months without stopping.

This ability to operate VIPR pumps as paired or stand-alone pumps adds to the flexibility of these pumps and significantly expands their performance capabilities.

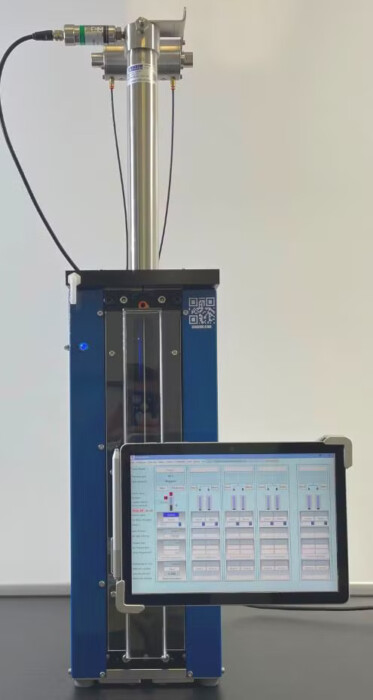

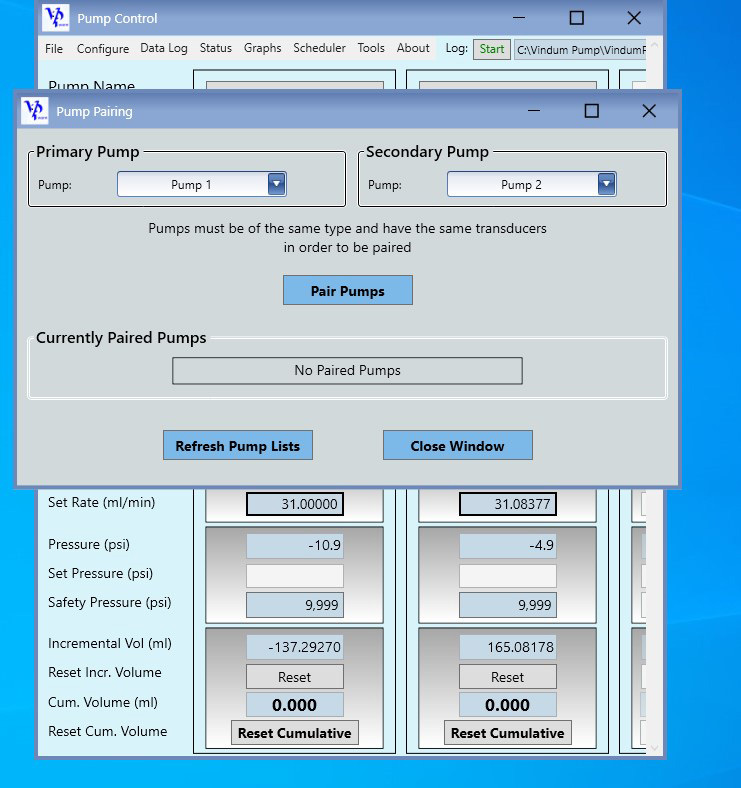

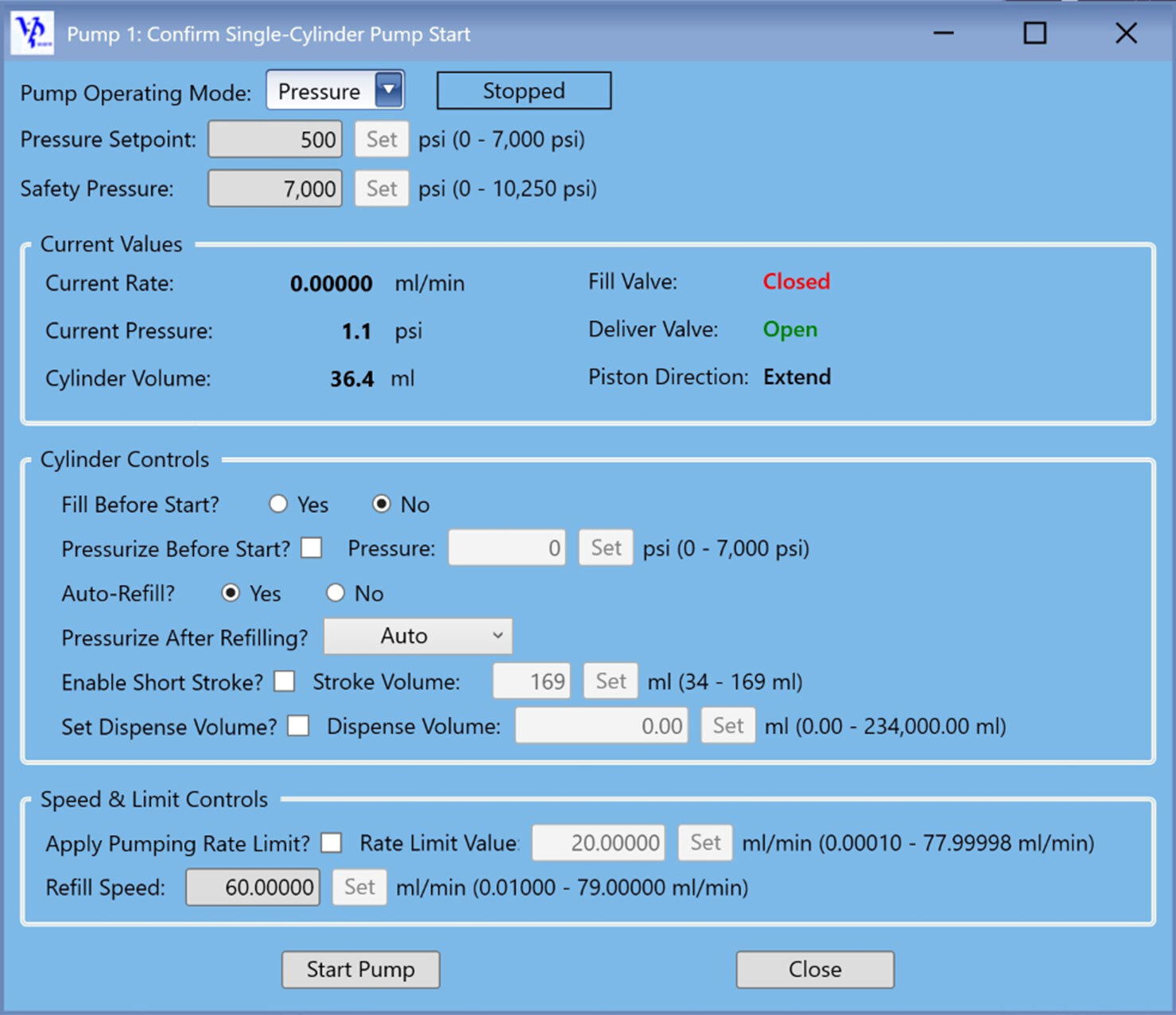

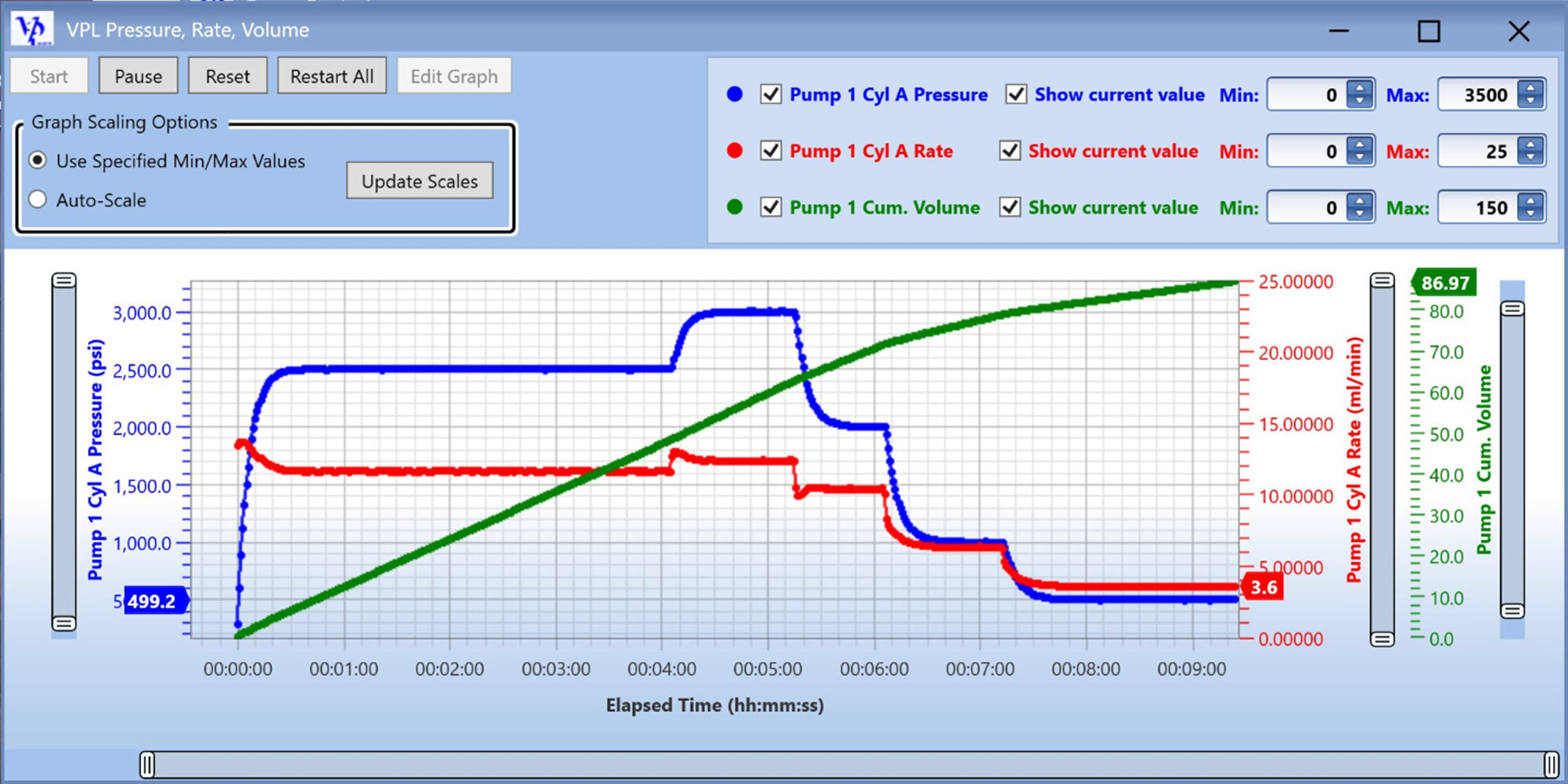

The VIPR-Series pumps use the same VPware PC-based software as our VP-Series pumps, so a single PC running Windows 7 or later can control several VP-Series and VIPR-Series pumps simultaneously. When two VIPR pumps are paired, VPware allows continuous constant-rate or constant-pressure pumping, as if the pumps were a single dual-cylinder pump. For single VIPR pumps, VPware presents a simplified control screen that allows the user to conveniently set pumping parameters in one place. Of course, features such as real-time graphing, data logging, and multi-step programming (Scheduler) are available in VPware for VIPR pumps.

VPware, developed by Vindum Engineering, is included (free) with the purchase of any VP-Series or VIPR-Series pump. VPware is the most advanced pump-control software of its kind. It has an intuitive interface that is friendly to new pump users while offering capabilities to meet the demands of experienced operators. The combination of VPware and VP-Series or VIPR-Series pumps delivers excellent performance, extensive features, and ease-of-operation to meet any user’s requirements. We are also happy to add new features based on customer’s needs.

VPware: Loaded with features

- Thirteen Pump Modes, , including pulse-free constant-pressure or constant-rate modes (deliver, receive, or bi-directional). Delta-Pressure and Recirculation (for core flood experiments) are also available.

- Volume or Time Dispense: : Precise pumping by fluid volume or time.

- Ramping Sequences: Build multi-step ramp sequences (ie, change pressure or rate as function of time or volume pumped) are easy to build and use.

- Pressure or Rate Following: Pump #2 follows rate or pressure of Pump #1, either as percentage or differential. Run ramping sequence on Pump #1 and Pump #2 will track its rate or pressure path automatically.

- Pump Group (Rate modes): Multiple pumps operate together to deliver/receive a combined fluid rate, with individual pump rates set as percentage or proportion of the total rate, or individual values.

- Data acquisition module: External device with analog inputs and digital controls.

VPware: Informative & Intuitive

- Intuitive pump configuration, operation, and status screens.

- Graphs that are easy to create, save, and view in real-time.

- Data log any/all pump parameters at up to 50 milliseconds intervals.

- Create pump schedules (rate or pressure) quickly and easily.

- Informative warning and error messages provide guidance and feedback.

- Error analysis records pump commands and data for easy troubleshooting.

- Control 16 pump simultaneously or run multiple VPware sessions concurrently.

Shown below are examples of the VPWare Main Screen, the Pump Configuration Screen, and the Pump Status Screen:

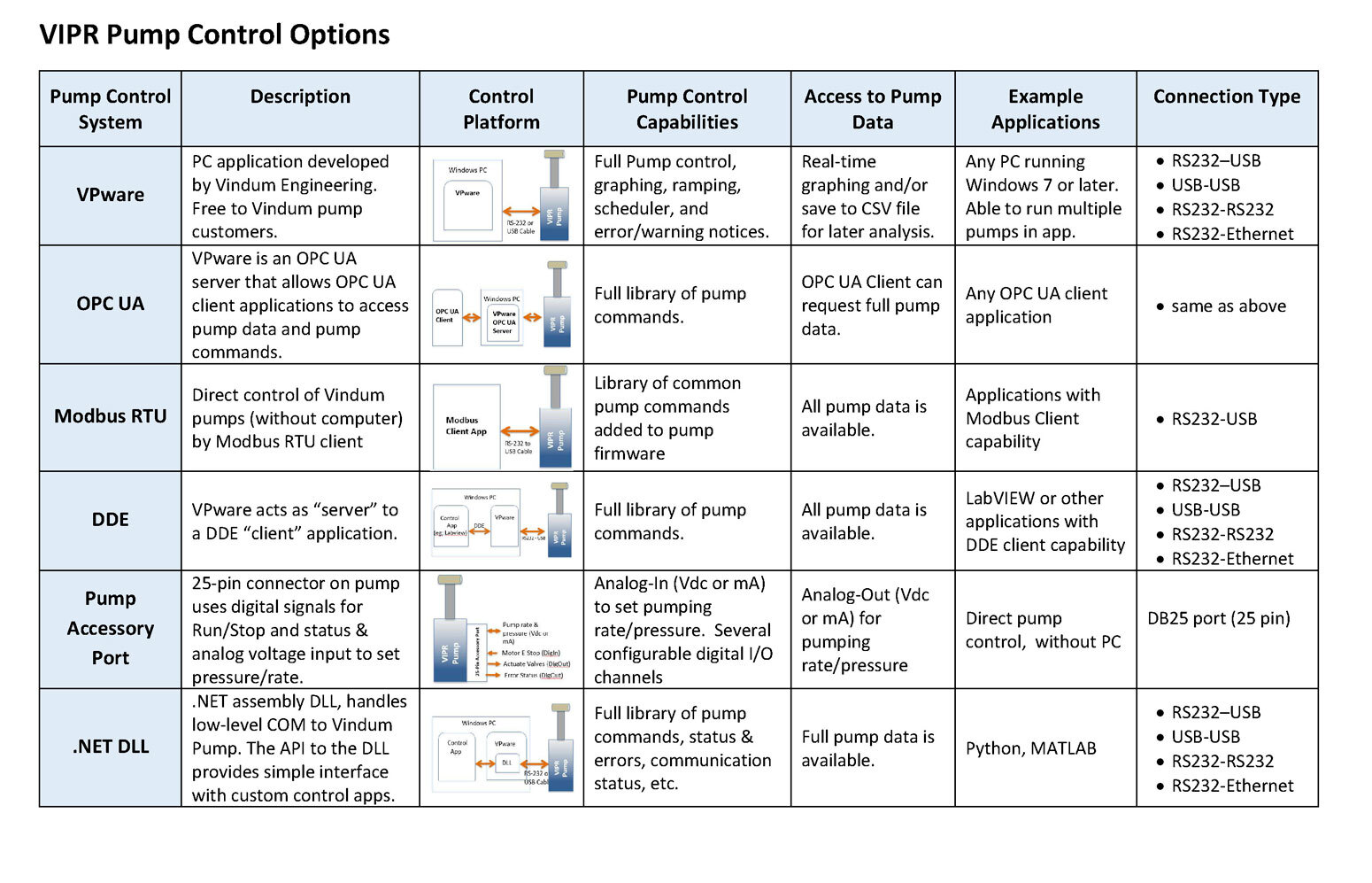

There are many ways to control VIPR-Series pumps. The table below lists some of the control options. Please contact Vindum Engineering to discuss the needs of your specific system.

Click here to Download the PDF Document.

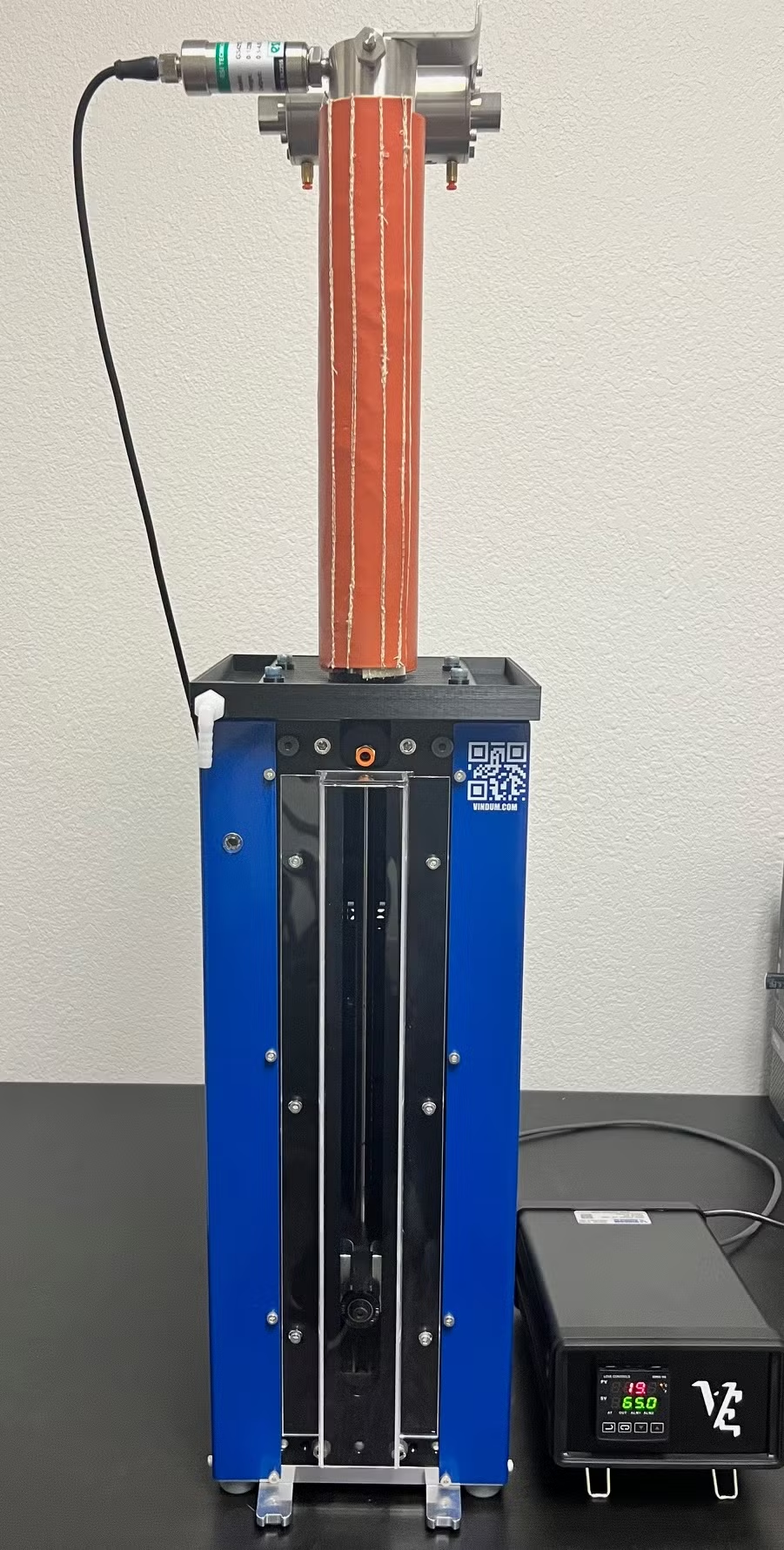

We offer two temperature-control jackets for VIPR Pumps:

- Temperature-Control Jacket is used to circulate cooled or heated water around the cylinder of VIPR pumps to cool or stabilize the temperature of the pumped fluid. This is helpful when pumping liquefied gases, to cool the incoming fluid to help minimize phase changes. The jacket has sealing O-rings at each end and is easily installed over the pump's cylinder. Heated/cooled water bath not included.

- Heating Jacket and Controller: The silicone foam jacket and the temperature controller (120-240VAC input) allow user-settable temperature to 160C. The jacket includes a Velcro closure, an embedded Type-J thermocouple, and an auto-reset temperature cutoff switch to prevent accidental over-temperature.

We've built our reputation on product quality and outstanding customer support. In addition to complementary training for new pump customers, we offer instructional videos that show how to maintain and service our pumps and valves, and detailed product documentation. Click on the YouTube link on this page (red button) to see available videos on the Vindum Engineering YouTube channel.

We strive to answer customer questions within 24 hours. If you have a question about your Vindum product, please email us (support@vindum.com or call us (+1 281-782-8312, ext. 1)

Pump customers can download the latest versions of pump-control software and the Vindum Pump User Guide in the Customer Area of this website (link at top of this page). If you do not have a customer account, please click on the CUSTOMER LOGIN link above and select REGISTER NEW USER to request account activation. All the content of the Customer Area is free to owners of our pumps.

For product inquiries, please contact us using the REQUEST A QUOTE button above.

Please complete the form below to request a User Guide or Login to your Customer Account