- Product Details

- Pump Design

- Specifications

- High-Temp Pumps

- VPware Software

- Control Options

- Wash Kit

- Support

- Loaner Pump

VP-Series High-Pressure Metering Pumps

Manufacturer: Vindum Engineering, Inc.

Model Number: VP-Series

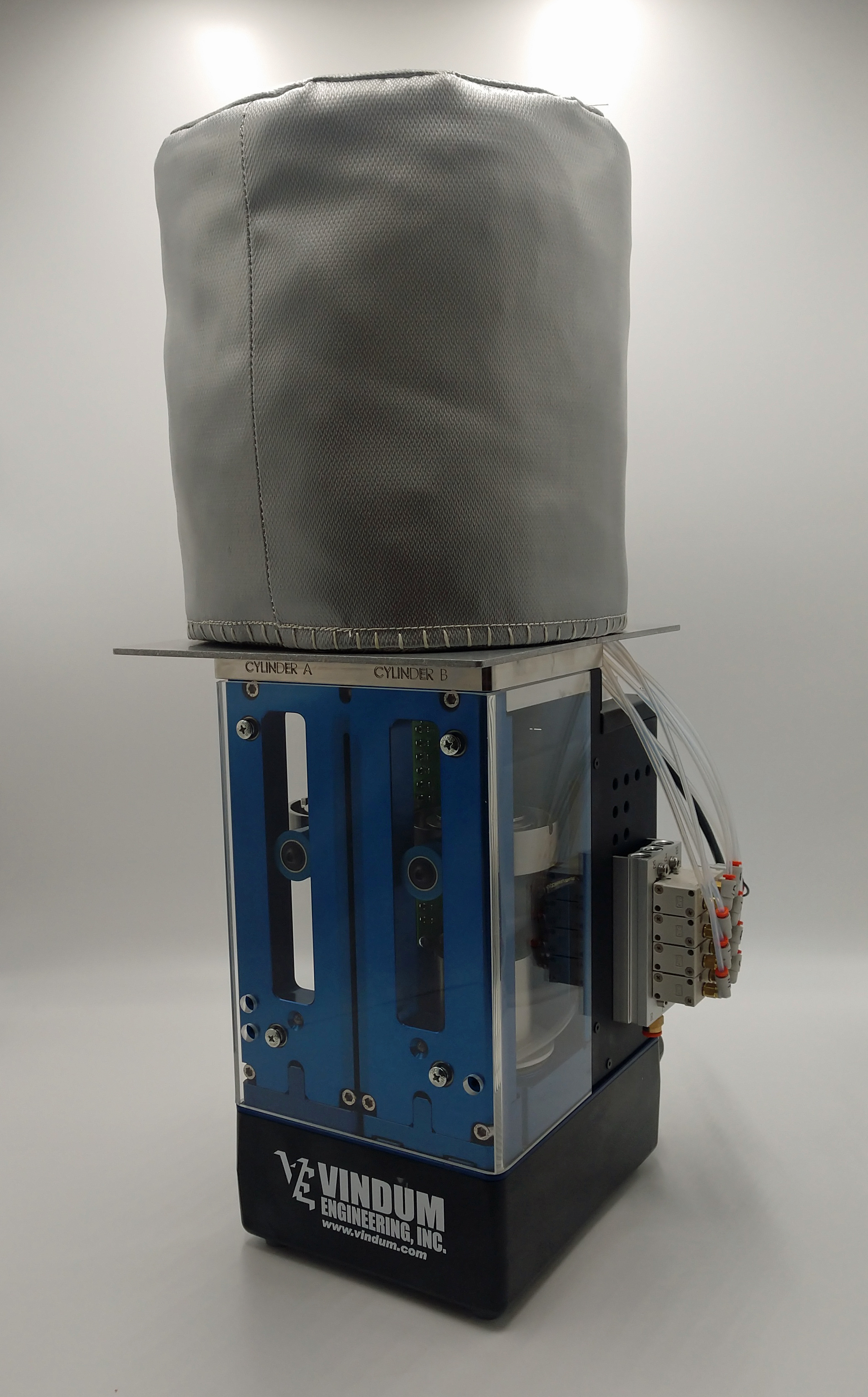

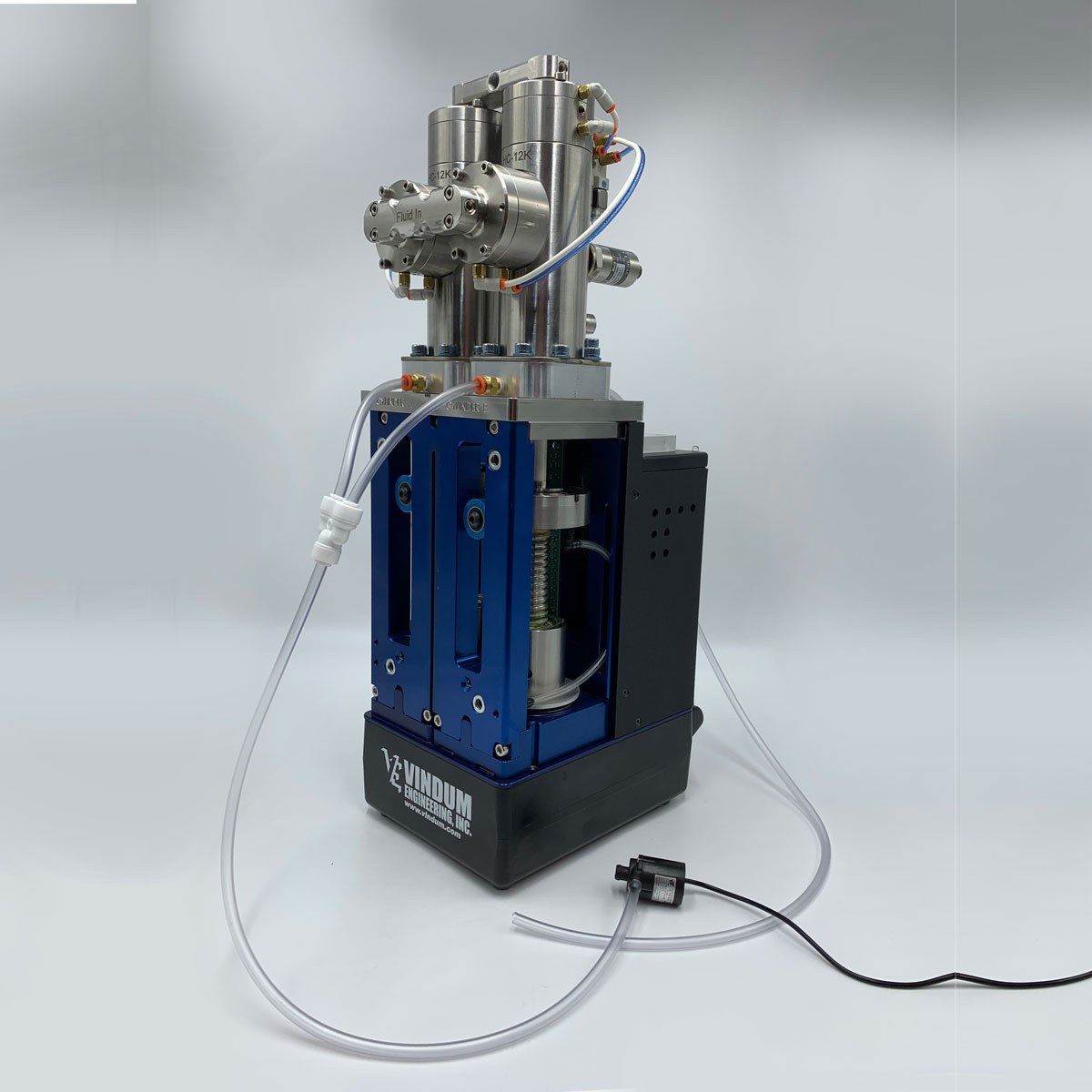

Vindum VP-Series pumps are dual-piston high-pressure metering pumps that deliver ultra-precise, pulse-free, continuous flow in either constant-pressure or constant-rate modes, at up to 25,000 psi. High-temperature versions allow wetted parts of the pump to be heated to 320°F (160°C). Leading-edge design, compact size, and attractive pricing make these metering pumps perfect for a wide range of applications.

Features include:

- Pulse-free continuous flow standard (pressure or rate modes)

- Flow rate range: 0.1µL/min—81ml/min (varies by model)

- Extreme pressure capability: 0 – 25,000 psi (varies by model)

- 13 modes: rate or pressure deliver, receive, bi-directional

- Advanced pump-control VPware software included (PC-based)

- Numerous alternate control/communication options (see Control Options tab)

- Easy to maintain and clean

- Ultra-compact footprint (19”H x 6”W x 9”D)

VP-Series Pump Applications:

- Coreflood and PVT Experiments

- Chemical, Catalyst or Biofuels Pilot Plant or Process Testing

- Continuous Additive Injection

- Processes involving corrosive fluids and/or high-temp fluid injection

Categories: VP Metering Pumps: High-Accuracy, High-Pressure, Laboratory Metering Pumps

Click on the animations below to see the VP-Series Metering Pump Internal Pump Operation and List of Features:

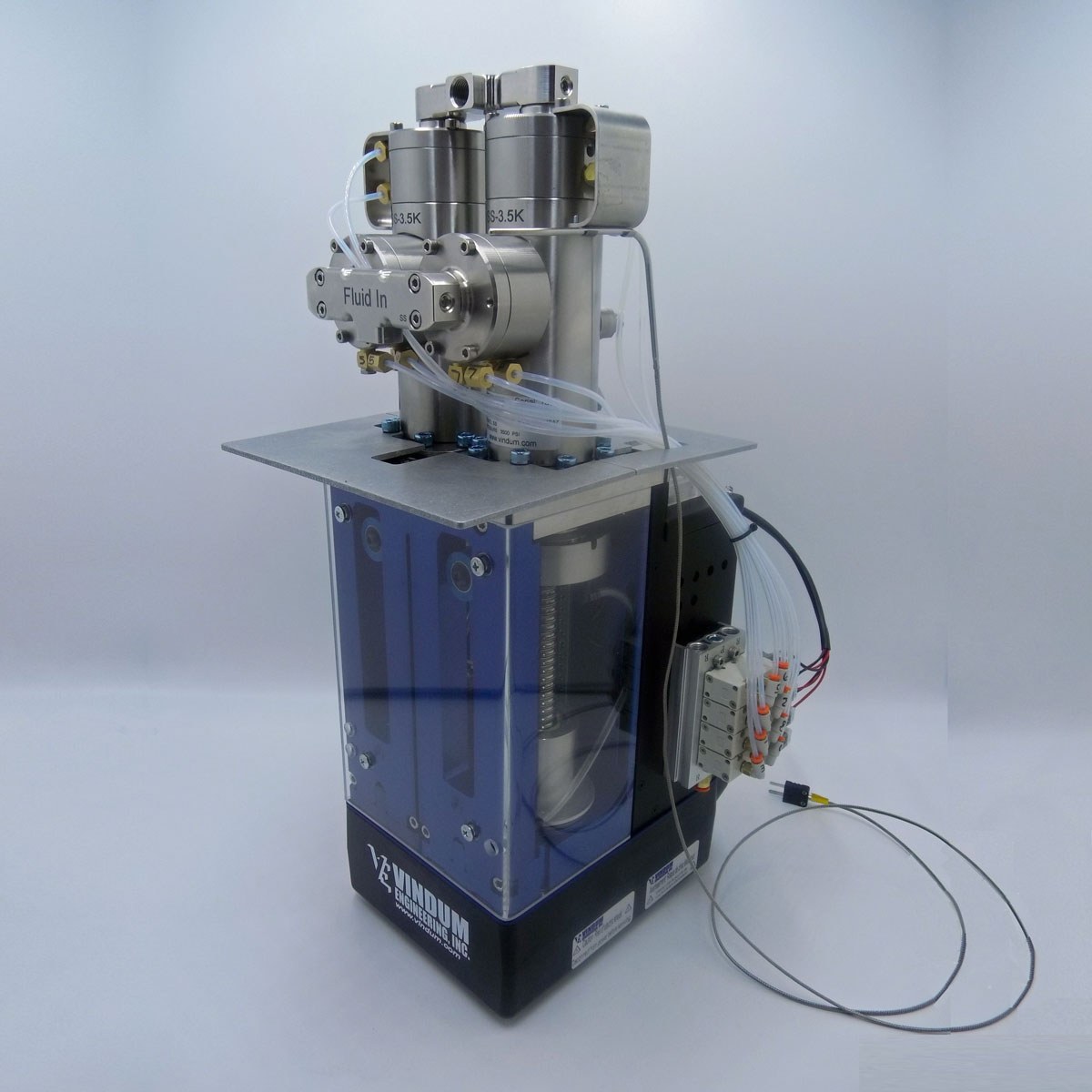

Design of the Vindum VP-Series Metering Pumps

- Dual-cylinder metering pump offering continuous pulse-free fluid flow and constant pressure

- Pulse-Free: Patented constant-volume valves eliminate pulses at switchover

- Ball-screw drives for accuracy & low maintenance

- High-accuracy transducers (0.1% error)

- Millisecond motor control

- 0.1 psi servo control ensures highest accuracy pressure control

- Zero-hysteresis gear drive system

- Valves, transducers, and safety burst discs integrated directly on cylinders

- USB and RS232 connectivity

- 110-240V / 50-60Hz power supply

Features of the Vindum VP-Series Metering Pumps

- VPware software (included with pump) is feature-laden & user-friendly

- 13 pump modes: set pressure or rate, fluid deliver, receive, or bi-directional

- Many pump control options: LabVIEW, Modbus, OPC UA & Industrial Ethernet networks

- Smallest footprint continuous-flow pump: much smaller than most single cylinder pumps!

- Modular design for easy maintenance. Top section can be removed with fluid inside, for easy cleaning

- Hastelloy wetted parts (optional) for use with corrosive fluids

- High-Temp. models can be installed into an oven or air bath to 320°F (160°C)

- Integrated emergency stop circuit

- 2-Year Warranty

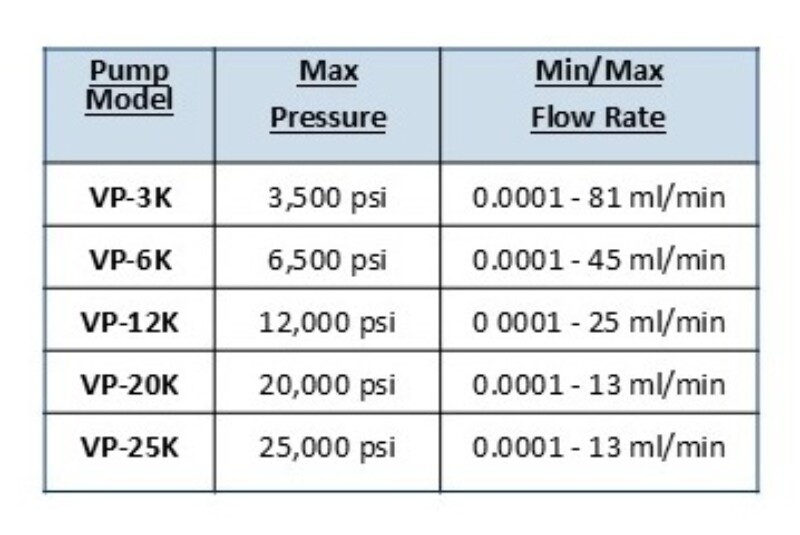

Specifications for VP-Series Pump models are shown in the table below. CLICK HERE TO DOWNLOAD PDF

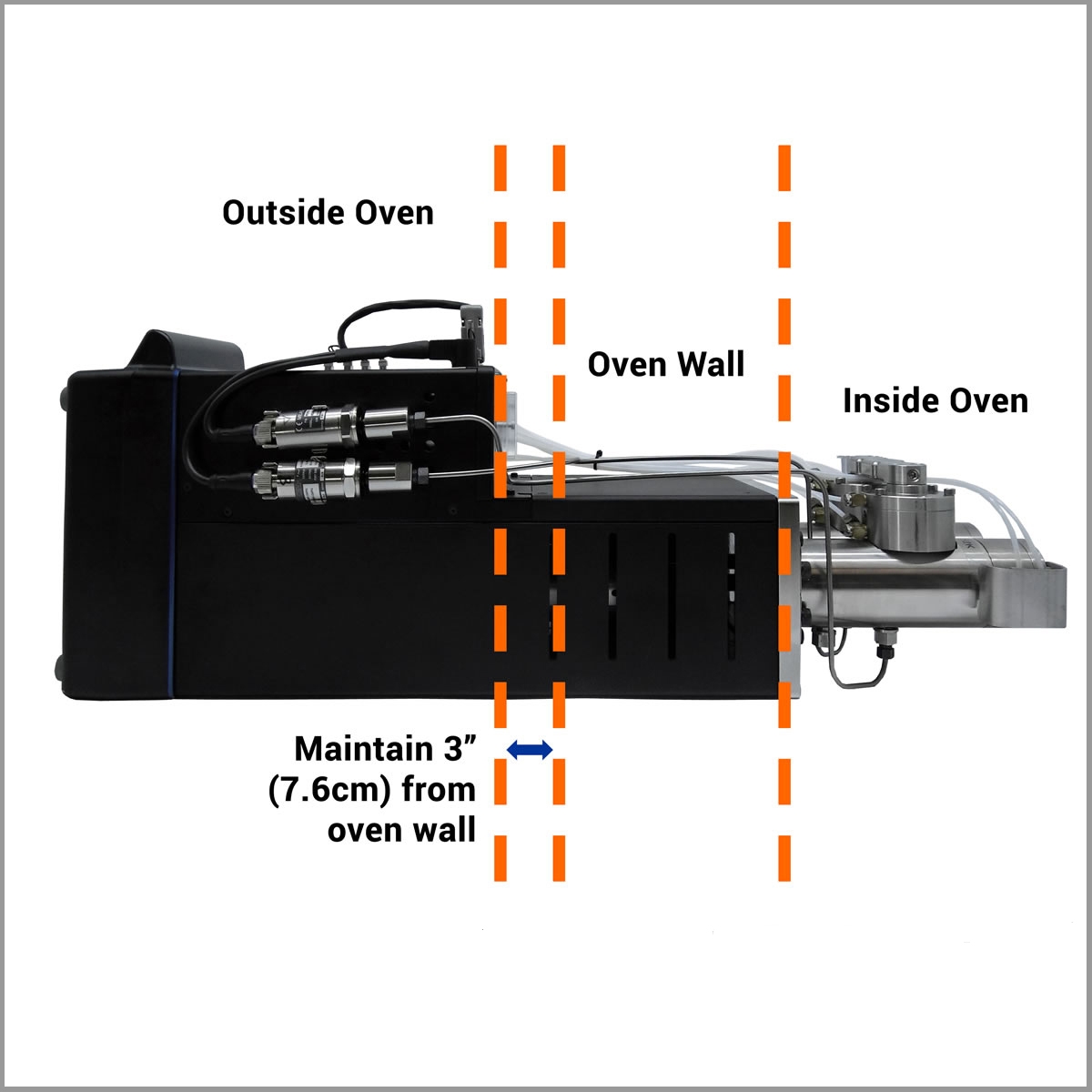

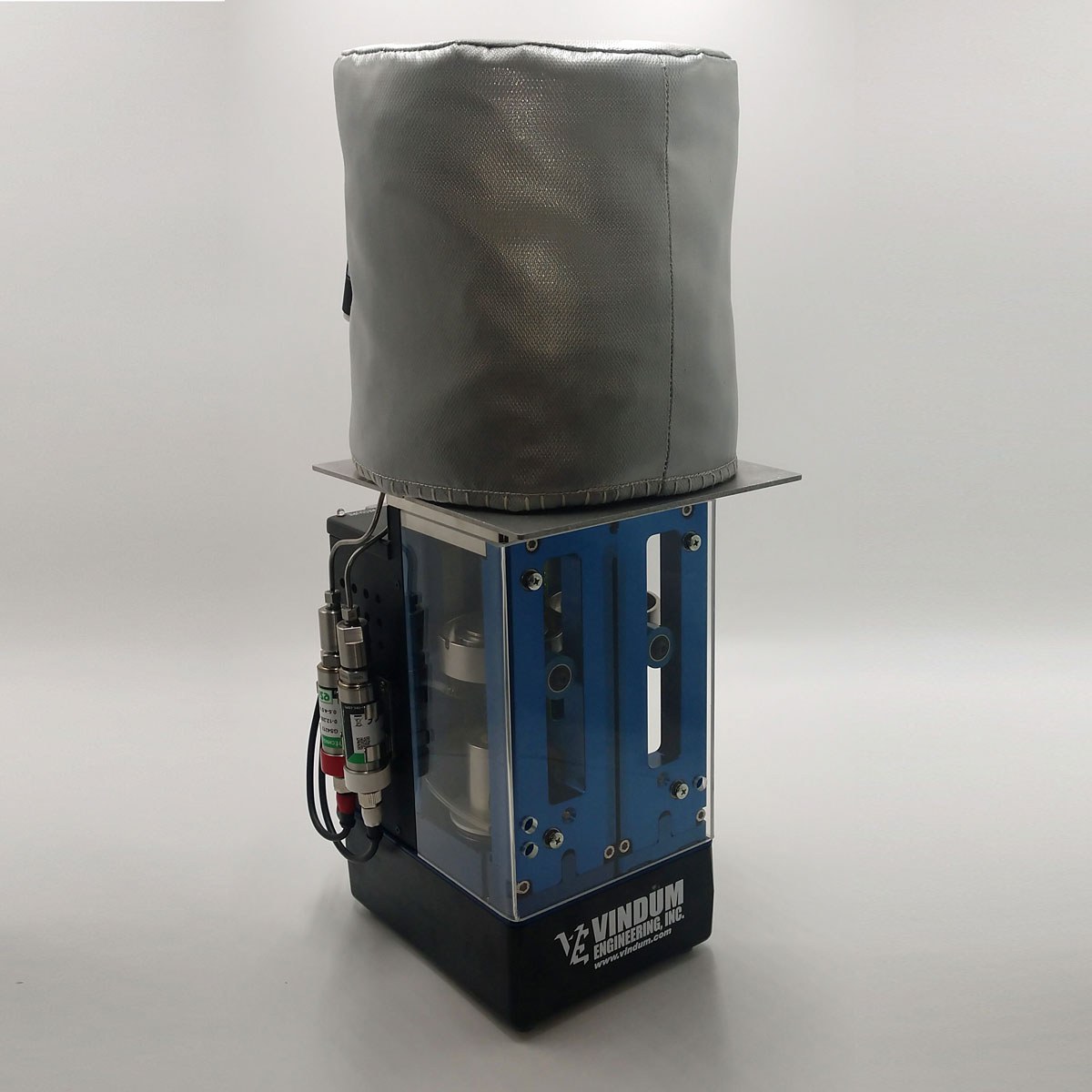

VP-Series High-Temperature Pumps

VP-Series pump options that are designed for demanding high-temperature applications, up to 160°C (320°F):

EXT Model

This model supports heating up to 100°C by using a heating jacket, or by pumping materials that are already heated.

HT Model

This configuration is suitable for temperatures up to 160°C. All wetted components can be placed inside an oven to ensure complete and uniform heating. It can also operate with a heating jacket or with pre-heated materials.

The VP-3K, VP-6K, and VP-12K pumps are available in either EXT or HT versions. If you would like additional details or specifications, you are encouraged to contact Vindum Engineering through the REQUEST A QUOTE button above. They will be very glad to assist you in finding the best solution for your high-temperature pumping needs.

Advantages that make the VP-Series pumps an excellent choice for high-temperature applications:

-

Engineered for durability: Special seals and pistons support reliable operation at temperatures up to 160°C (320°F), even during demanding, long-duration processes.

-

Protected electronics: All sensitive electrical components remain outside the oven, which helps extend service life and maintain consistent performance.

-

Space-saving design: The compact footprint (26" H x 9" W x 10" D) requires very little oven space, making it well suited for crowded labs and pilot facilities.

-

Flexible installation: The pump can be placed horizontally or vertically inside the oven, allowing you to adapt to your workspace and process requirements.

-

Multiple pressure options: Available in 3,500 psi, 6,500 psi, and 12,000 psi models with either stainless steel (SS) or Hastelloy C-276 (HC) wetted parts to support a wide range of fluids and conditions.

-

Proven performance: You will experience the same reliable operation and flow control that users appreciate in standard VP-Series pumps.

These capabilities are designed to help you work with confidence when your process demands precise, high-temperature pumping performance. If you need guidance selecting the right configuration, feel encouraged to reach out for support.

VPware is a PC-based software application, developed by Vindum Engineering, to operate the VP-Series pumps. It is included (free) with the purchase of any VP-Series pump. VPware is the most advanced pump-control software of its kind. It has an intuitive interface that is friendly to new pump users while offering capabilities to meet the demands of experienced operators. The combination of VPware and VP-Series pumps delivers excellent performance, extensive features, and ease-of-operation to meet any user’s requirements. We are also happy to add new features based on customer’s needs.

VPware: Loaded with features

- Thirteen Pump Modes, , including continuous pulse-free constant-rate or constant-pressure modes (deliver, receive, or bi-directional). Delta-Pressure and Recirculation (for core flood experiments) are also available.

- Volume or Time Dispense: : Precise pumping by fluid volume or time.

- Ramping Sequences: Build multi-step ramp sequences (ie, change pressure or rate as function of time or volume pumped) are easy to build and use.

- Auto-Prime Feature: Automatically fills pump with fluid and verifies that residual air is eliminated from cylinders prior to start.

- Pressure or Rate Following: Pump #2 follows rate or pressure of Pump #1, either as percentage or differential. Run ramping sequence on Pump #1 and Pump #2 will follow its rate or pressure path automatically.

- Pump Group (Rate modes): Multiple pumps operate together to deliver/receive a combined fluid rate, with individual pump rates set as percentage or proportion of the total rate, or individual values.

- Data Acquisition Module: External device with analog inputs and digital controls.

VPware: Designed to help you work with confidence and efficiency

-

Clear and intuitive screens allow you to configure, operate, and monitor pump status with ease.

-

Real-time graphing tools are simple to create, save, and review, giving you immediate insight into system performance.

-

Flexible data logging captures any pump parameters at intervals as fast as 50 milliseconds, supporting detailed process analysis.

-

You can build pump schedules based on rate or pressure quickly, helping you streamline test setup and execution.

-

Helpful warning and error messages offer meaningful guidance so you can respond and continue your work with minimal interruption.

-

Error analysis features record pump commands and data, supporting efficient troubleshooting and faster system optimization.

-

VPware can manage up to 16 pumps at the same time, and you may run multiple VPware sessions concurrently for advanced control needs.

VPware is designed to support smooth operation, clear visibility, and dependable control, helping you achieve highly accurate and repeatable results.

Shown below are examples of the VPWare Main Screen, the Pump Configuration Screen, and the Pump Status Screen:

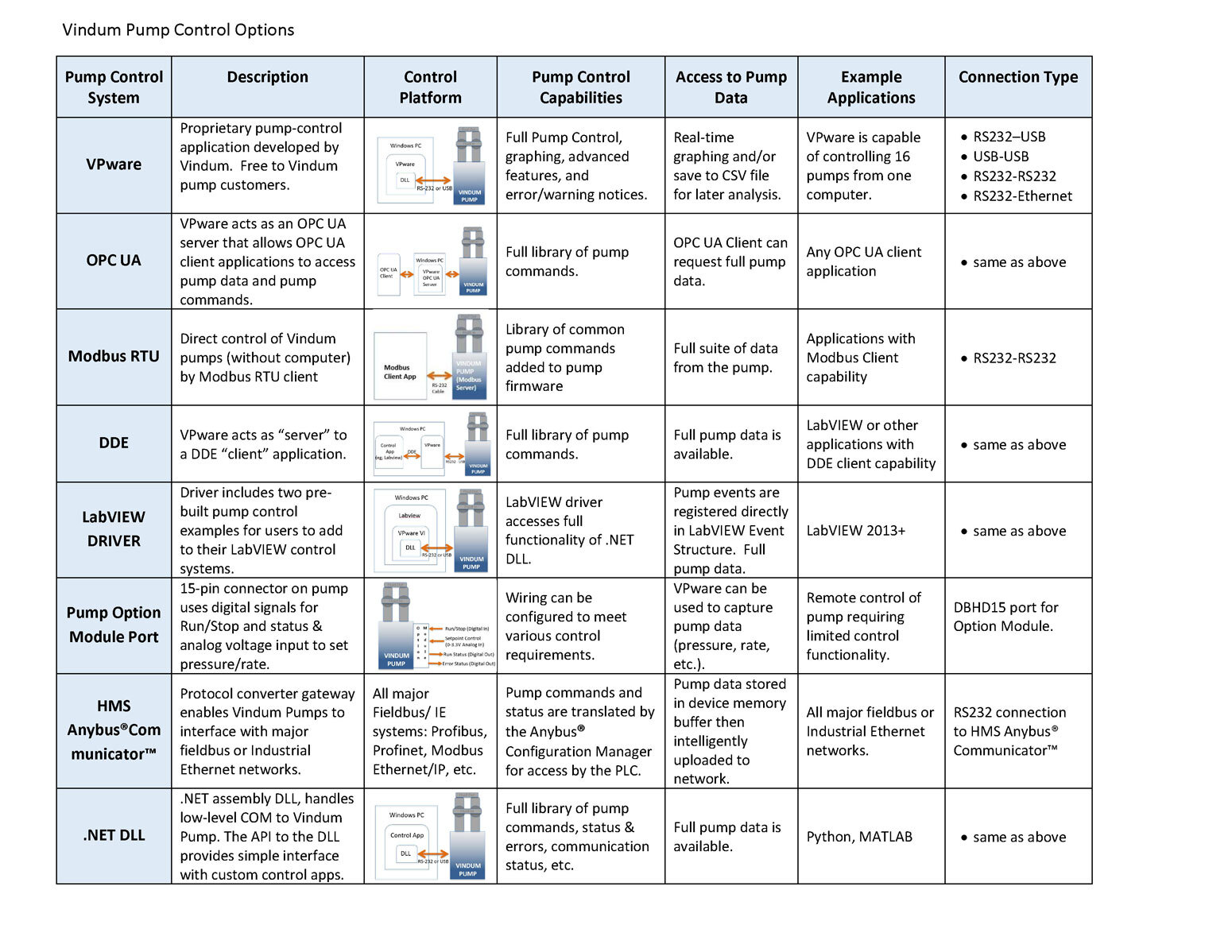

There are several control system options available for the VP-Series pumps. These are summarized in the table below. If you have any questions or need another control method, please contact us at support@vindum.com.

The hardware-level control format for VP-Series pumps is serial/binary (non-ASCII) with cyclic redundancy check (CRC), using byte string command-response protocol. All communications from the pump are in the form of responses to commands; the pump does not send any unsolicited messages. This communication format has been adopted because of the efficiency/speed that it offers compared to other forms of communication (e.g., ASCII). A .NET DLL (Dynamically Linked Library) is layered over the serial code to provide software developers with a simple PC-based API (Application Programming Interface) for pump control. VPware and the VPware LabVIEW Driver use this DLL. Beyond PC-based controls, the pumps also have an additional port that provides limited analog/digital pump control. For pump control with Fieldbus and Industrial Ethernet systems, we offer configuration for HMS Anybus® Communicator™, a protocol converter device that enables our pumps to be used in all major Fieldbus/IE systems.

Click here to Download the PDF Document.

Pumping fluids that contain dissolved salts, such as brines, may lead to salt deposits forming on a pump’s pistons. Over time, these deposits can contribute to wear on piston seals and may shorten service intervals. To help you avoid these issues, a dedicated piston wash kit is available.

This system provides a continuous rinse with distilled water, helping to keep the pistons clean during operation. It is designed for simple installation and can be added to existing pumps at any time. The complete kit includes all components shown in the product photos.

If you would like to explore whether this solution is right for your application, you are encouraged to reach out to Vindum Engineering through the REQUEST A QUOTE button above. They will be glad to support you in selecting the best options for reliable, long-term pump performance.

Your experience matters, and you can count on reliable product quality supported by attentive customer care. New pump customers receive complementary training, and you also have access to clear instructional videos that demonstrate how to maintain and service pumps and valves. You are invited to view these VP maintenance and service videos on the Vindum Engineering YouTube channel or through the CUSTOMER LOGIN link above.

Pump owners may download the latest VPware software and the Vindum Pump User Guide through the Customer Login area of this website. If you do not have an account yet, simply click CUSTOMER LOGIN and select REGISTER NEW USER to request activation. All resources in the Customer Area are offered at no cost to Vindum pump owners, supporting smooth operation, dependable performance, and long-term confidence in your equipment.

The support team works hard to respond to customer questions within 1 business day. If you ever need assistance, please send an email to support@vindum.com or call +1 281-782-8312, ext. 1. You will be welcomed, and your questions will be addressed with care.

For new product inquiries, you are encouraged to use the REQUEST A QUOTE button above. The team will gladly guide you toward the best solution for your application.

Please complete the form below to request a User Guide or Login to your Customer Account

Vindum Engineering offers a “loaner pump” program, which gives prospective customers the opportunity to try a VP-Series pump in their facility for a period of time (typically 4-8 weeks). If interested, please fill out the form below with your information.

While we cannot accommodate every loaner pump request or commit to having a loaner pump available at all times, we are committed to offering new customers the opportunity to work with our pumps so that they can experience their performance first-hand.

Privacy: We value your privacy and will not share your information with any third parties